The Department of Energy would like builders to up their game. Though it is worth celebrating the average 20% greater energy efficiency advertised by the Energy Star for Homes program, these days it’s possible to build homes that are even more energy efficient than that. It’s even possible while also delivering other key benefits: improved comfort, reduced water use, the best possible indoor air quality, and the ability to seamlessly integrate solar PV. The DOE thinks it’s time for more new homes to take that step.

Enter the Zero Energy Ready Home program. Launched in 2013 as an outgrowth of the DOE’s previous Builder Challenge program (which saw 14,000 homes certified), this new home certification program requires a home to perform several steps above Energy Star. According to Jamie Lyons of Newport Partners, a management firm that helps the DOE administer the program, ZERH Certification has grown twofold from 2016 to 2018. As of late 2018 there were several thousand homes certified across the country, with approximately 10,000 in the pipeline to be certified.

Green Built Alliance member company Deltec Homes just built the region’s first Zero Energy Ready Home, after having built 100% Energy Star Certified homes, and many Green Built NC Homes, for many years. (The home was Rated by Green Built Alliance member company Vandemusser Design.) When adding this new certification we learned some things along the way that made us into better builders, and we thought we’d share those things here.

A Lot like Energy Star, With Substantial Add-Ons

The insulation and comfort system requirements for Zero Energy Ready Home are a bit beefed up from Energy Star, but in our case, we were already doing most of those. The biggest design difference is that ZERH requires all ductwork to be 100% inside conditioned space, whereas Energy Star merely rewards it. This makes sense, as moving ductwork inside conditioned space offers notable energy efficiency gains—one study found it can save between 8% and 15% on air conditioned costs.

In this home design: a 1762 square feet custom “Ridgeline” model built on a slab foundation and incorporating a split monoslope roof design with vaulted trusses, we typically build a conditioned attic space over a central core of hallways and bathrooms, using spray foam insulation at the roof line and exterior attic walls. We typically house a single ducted mini-split in this mini attic space, with ductwork adequate to serve the bedrooms and bathrooms that are all clustered on the back half of the house. We then serve the open kitchen, living and dining half of the house with a single ductless mini-split. This two zone system is our attempt at striking a compromise between right-sizing the unit’s capacity to the house heating and cooling load while also distributing the conditioned air effectively throughout the house. In our area we have seen many contractors who are using mini-splits put one ductless unit in every bedroom, even in very well insulated homes—a design we think is overkill from a capacity and equipment cost standpoint.

The Reduced Hot Water Use Requirement Was the Kicker*

There is a little requirement, buried within the ZERH program documents, calling for efficient hot water distribution. From the ZERH checklist, V4: “to minimize water wasted while waiting for hot water, the hot water distribution system shall store no more than 0.5 gallons of water in any piping/manifold between the hot water source and any hot water fixture,” a requirement that must be measured by the Rater. Since most homeowners flush the colder water down the drain while they wait for the heated water to arrive, this requirement can save a considerable amount of water. Yet a water heater would have to be located close enough to all the faucets store this little water in the piping between them. Having to think about this might be completely new to a builder who has only built for Energy Star, and indeed, is unusual as an absolute requirement for a green building program, rather than an option for additional points.

A quick glance at the floor plan had me convinced, at first, that this project was not going to meet this requirement, as the water heater was on the far side of the house from one bathroom. Yet, we had specified a heat pump water heater for its superior energy performance over a typical electric tank water heater, a technology that the homeowners agreed to despite the operating noise and the cold air put out by the heat pump technology, only if they could keep this water heater away from the main living spaces. Since the home was on a slab foundation, moving the water heater under the house to be centrally located underneath the baths also wasn’t an option.

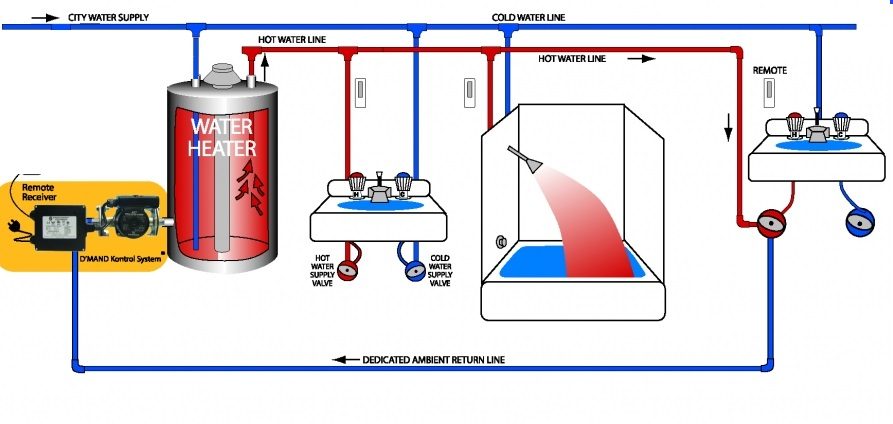

I spoke to the friendly folks at the DOE about this challenge, who pointed out that ZERH does allow this plumbing design but requires a hot water re-circulation system to quickly deliver hot water to distant fixtures, so long as that system has the right kind of controls. In a typical hot water re-circulation system, an extra hot water return line makes a loop between the furthest fixtures and the water heater, while a pump is set up to circulate hot water throughout this loop. When hot water is called for, that water only has to travel the distance from the loop to the faucet, not the entire distance from the water heater to the faucet, reducing the amount of water that is wasted down the drain while waiting for the hot water to arrive. Long wait times for hot water is a complaint I’ve heard from homeowners before (this issue is probably made even more noticeable by lower flow fixtures). These very homeowners had even asked me once, in an offhanded sort of way, if there was a way to avoid wasting so much water.

The thing is, For Zero Energy Ready home, this pump cannot be activated by a timer. It must be controlled with either a manual button, an adaptive control system, or an occupancy sensor that turns the pump on when it senses someone near the faucet. According to the folks at the DOE, and backed up by conversations I’ve had with our own Energy Rater, many of the common methods of controlling a hot water re-circulation pump (such as timers or temperature sensors, or even just leaving the pump on 24/7) end up wasting energy rather than saving it, as the system often end up operating when hot water is not actually called for. Unfortunately all of the re-circulation pumps that our plumber or their plumbing supply house were familiar with used timers to control the system.

Luckily the DOE has some suggestions for recirculating pumps with manual controls. After researching several options, I settled on the D’Mand Kontrol system with user-activated buttons. The system even includes LED switches that light up when the pump is activated, to alleviate the problem of one person hitting the button in one location and another inadvertently turning it back off by hitting it somewhere else. It took some research to find a supplier for the D’mand Kontrol system, and some convincing to get our plumber comfortable with installing it. (“Yes, I specifically need one that can do manual control. No, I can’t accept this alternative that uses a timer.”) It took some coordination between the plumber who would install the pump and the electrician who would install the low-voltage wiring between. But in the end, we did get it working, and had a new selling point to offer any customer, not just those interested in a Zero Energy Ready Home: no more water wasted waiting for hot water to arrive.

(*As of 5/8/2019, the DOE released a new revision on the program that has additional options for the efficient hot water requirement that were not in effect when we completed the program. However, we think that the hot water re-circulation pump with demand control is such a good idea we did still want to share our story about it!)

A New Focus on Interior Finish Selections

ZERH Certification requires that the homeowner also earn Indoor Air Plus Certification, another green certification program available from the EPA with specific requirements for indoor air quality. Many of these requirements also overlap with Energy Star, such as right-sizing your HVAC system, installing a fresh air ventilation system, and incorporating key water management details in the building envelope.

Some requirements were new to us, and required that each interior finish selection be carefully vetted. Any composite wood product (including any cabinetry, plywood sheathing, trim material, or engineered wood flooring that had a composite wood component), any interior paint or stain, and any carpet and even the carpet pad, had to comply with a relevant indoor air quality standard. While some of these standards were easy to identify (for example, the carpet product selected had the required CRI green label clearly documented on the spec sheet, and our paint supplier was already using the Sherwin Williams Pro-Mar 200 Zero-VOC line) others required considerable research to uncover.

The interior doors proved the most interesting challenge, as the ones we typically order come from a small regional manufacturer rather than a national supply house, and we uncovered during the vetting process that they were composed of materials assembled on site from various other manufacturers. Multiple phone calls to various management levels of the manufacturer of each component were needed to ensure that the doors were in fact CARB phase II complaint. Then it took a special order from the supplier to ensure that doors arrived on site that carried the CARB II sticker to prove it.

Ask, verify, and then verify again is a good manta for this kind of product specification research. We were pleased to be able to work with our normal supply companies for our interior products and not disrupt our typical ordering process, mostly because I was willing to put in the research and did so well before it was time to order. Some builders may just want to be sure to order key components from national suppliers, who often have better documentation on the various VOC certifications their products hold.

Solar Ready

“Zero Energy Ready Home” is not my favorite program name, I admit it. I am skeptical that the concept of “zero energy” would makes sense to most customers and can even sound misleading (Is it zero site energy? Zero source energy? How is it really zero energy in a typical net-metered situation? What do you mean my home is ready for zero energy but isn’t necessarily zero energy?) I do get it—the concept of being “ready for zero” is about a home that’s puts efficiency first, so that solar is easy and simple. In our case, solar was already part of the project. Our area has a decent net-metering program, and local rebates for solar offered through Duke Power that the homeowner wanted to take advantage of. Without solar, a home participating in ZERH has to complete a solar-ready checklist which include provisions for planning for future solar.

Benefits and Considerations

In the end, the homeowners got a highly efficient home, with tested systems, better air quality, and reduced hot water wait times. We were fortunate that we were able to do so without compromising on the specific technologies (like the heat pump water heater) or the specific selections (like those cabinets they really had to have…) that the clients had had made. We, meanwhile, gained a few new tricks and practices to employ.

The world of voluntary green building certification programs is already a crowded one, and the sheer number of programs to choose from can be confusing for a homeowner or builder to navigate. But having gone through it now, I have to say it that the ZERH program might now be my favorite program (outside of our own Green Built Homes, of course!) Unlike some of the more complex programs, it’s all encompassing. Everything is required, nothing is optional–yet the program is simple enough that it focuses on only the best, most universal practices in building science, without getting distracted by other green building practices that are nice to have but may not fit with every job. It builds on programs and concepts that are already out there—like the Energy star and Indoor Air Programs that are subsumed within it, but takes things further.

I think it’s a solid choice, not just for a “pretty good house”, but maybe even a darn good one.

Leigha Dickens is the Green Building and Sustainability Manager for Deltec Homes.